Thorough disassembled cleaning is better than spray-n-pray

When something as simple as cleaning is not detailed, what can be expected for more complex issues? Can deliberate avoidance of inspection provide assurance of continued service, or is there some level of “expectation” that nothing serious must be present? Therefore, (some might conclude) why be comprehensive, when in most cases, it is not truly necessary? What if it is your mechanism that contains an undiagnosed condition?

It has been found out that some offers for gun cleaning has actually been nothing like a complete teardown, but instead relies on some combination of soak, scrub, or spray. The clue is that it is at a price too low for professional gunsmithing shops that provide experienced personnel that thoroughly remove and detail inspect the parts after cleansing, prior to reassembly and any testing.

When more in-depth work is done by non-professionals, it is usually field stripping – removal of major assemblies – but they are not getting more than that soak or spray and/or toothbrush etc. to remove accumulation. There may also be some extended soaking or (in a few cases) even an ultrasonic cleaner dunk, but still with some parts not removed. There can be no in-depth flushing of any recess, blind holes, screw threads etc. while parts still occupy those spaces, so no assurance of removing crud that could cause malfunction. That type of cleaning is no more appropriate to long-term results than washing without removing clothing – the cleansing and inspections will be incomplete. Such shortcuts should only be considered as an expedient method for limited term results and not as providing long term reliability.

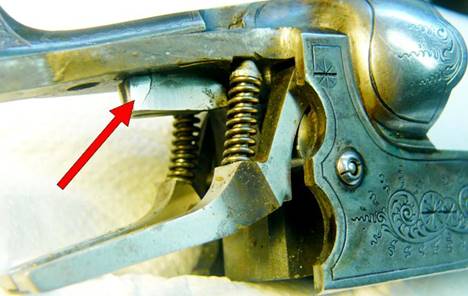

If your mechanism had this level of contamination, would you want a “cleaning” to be only a bit of spray and brushing, or would you be more comfortable with a thorough disassembly to get the crud and rust off all surfaces?

If this mechanism had not had the stock removed, the (red arrow) indicated crack might not have been diagnosed, and a top lever spring failing during a hunting trip would become a disappointment that could/should have been avoided by professional exam.

When a complex frame mechanism is completely apart, the most efficient exam and verification of parts condition becomes possible. Realize that there is a difference between what is expected and what is accomplished – if there is room to stretch a definition by avoiding the details of what specifically is being offered. This is the thorough type of work done here to verify that your problems are dealt with properly. Make sure that pertinent details are provided by any shop you patronize in order to avoid disappointment later.

Gun Shop

PO Box 212, Arnold, MO 63010

636-282-4379

yourgunsmith@hotmail.com 742gunsmith@gmail.com

Lever Action not Levering

A shooter is bound to be disappointed when the trip to the range is interrupted by a jammed gun. A brand new firearm that refuses to operate is a natural frustration. The temptation to attempt a fix is more than some might withstand, especially if the design is not apparently complex or requires obviously specialized tools. One such unfortunate set of circumstances is the subject.

See picture 1.

Start with a new 30/30 lever action and a frozen lever that absolutely refuses to stroke from the closed position. Grab for the hammer, but then restrain yourself. A screwdriver can pry, and if that doesn’t work, let’s start removing screws. Now that the lever is loose, a pair of other screws looks sufficient to get the lower trigger plate free, but things don’t quite work that way.

The bolt seems to be able to slide with the lever removed, but since the trigger plate is more complex to disassemble, the repair appears futile. The lever can be more easily inserted back into position while the bolt is partially open, and then the remaining two screws can be re-installed. Now the bolt can be moved somewhat by the lever, but it can’t get anywhere near closed or open, even with force against the lever. One problem has become two. Where’s that screwdriver?

Picture 2 shows the jam limit of closing.

Picture 3 is the clue to problem two.

The gun maker has choices when designing a series of parts for ease of manufacture. There are times when common threads are used on similar screws, but if the differences are subtle enough to allow an apparent interchange, problems that transpire afterwards may not be readily diagnosed. I would have included a change in the head diameter to preclude any inadvertent interchange.

Picture 4 shows the aftermath.

When similar screws are swapped, the shorter one may not have a problem fitting, but the longer one may protrude where interference is unwelcome. Such was the case when the lever no longer had clearance to freely swing through the normal arc of travel. Resistance was felt, so excess pressure was applied along with repeated hard stroking against the new artificial limit. Once the metal was upset on the lever (as pictured) by the longer screw thread end, the stroke of the lever in the opposite direction had that burr scraping in the trigger plate clearance slot. Picture 2 shows the arc point of that lever interference.

That ding mark can be minimized along with the induced burr inside the trigger plate slot, and minor screw thread end abuse is repairable. The original problem of the immobile lever is still present, but the lever travels freely after all the pry marks, burrs, and dings are remedied. Except! The lever won’t completely close now, and the trigger block isn’t being sufficiently depressed to allow the hammer to be lowered or fired. The final clue appears from the fog.

The finger lever plunger (latch that secures the lever in the closed position) can’t be completely compressed, so it can’t override the cross-pin to completely latch. The plunger is located just in front of the trigger in picture 2.

See picture 5.

See picture 6.

The manufacturer appears to have blued the lever with the plunger already installed in this instance, or else an insufficient rinse failed to dislodge retained bluing salts. Since some salts had not been sufficiently removed during the process, the limited free space then available made the plunger travel insufficient for proper latching action.

The final picture emerges: the tiny amount of salts in a plunger hole kept the plunger from fully depressing, so the lever could not be opened. That is similar to a doorknob that can’t be sufficiently turned to withdraw the latch from the strike plate in the doorframe. The owner let frustration assist in making ill-advised choices that compounded the troubles. This object lesson shows why anger or frustration should never be allowed to affect your judgment.

Gunsmithing

P.O. Box 212, Arnold MO 63010

636-282-4379 yourgunsmith@hotmail.com